Applications: glass bottle (testing the glass shards at bottom)

Specification| Max detection accuracy | lead: φ 0.2mm; stainless steel ball: φ 0.4mm; ceramic ball: φ 0.8mm; bone: φ 0.8mm; glass: φ 1.0mm | |

| Inspection dimension | max width | mm |

| max height | mm | |

| Max dimension allowed to pass | 350*310mm (width*height) | |

| Conveyor belt width | 85mm | |

| Conveyor height | 1100±30mm | |

| Conveyor speed | 10-100m/min | |

| Bearing capacity | 10Kg | |

| X-ray output | 40-80kVp/0.2-5mA | |

| X-ray leakage | < 3μSv/h | |

| Detector | linear scanning | |

| X-ray direction | double light | |

| Pixel size | 0.4mm | |

| Monitor | 15-inch LCD touch screen | |

| Operation method | by touch screen | |

| Software | Intellisense X-ray Inspection System | |

| System | Windows 7 | |

| Port | USB | |

| Parameter setting | manually/automatically | |

| Shell material | SUS304 | |

| Conveyor material | PU belt | |

| Air conditioner | internally-circulated industrial air conditioner; automatic temperature control | |

| Protection method | removable protective curtain | |

| Cleaning | cleaning job is done conveniently for the conveyor belt can be removed without tool | |

| Power supply | AC220/230V, 50/60Hz | |

| Environment | temperature: 5-35℃; humidity: 30-85%RH (no condensation) | |

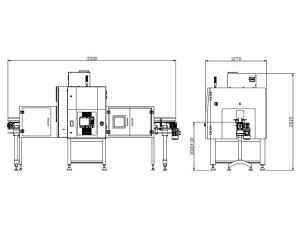

| Machine dimension | 3500*1300*1795mm (L*W*H) | |

| Machine weight | 700Kg | |